Tubular motors have become the go-to actuation solution for roller shutters, blinds, awnings, projection screens, and a growing range of architectural and industrial systems. Their compact cylindrical form factor allows the entire drive unit to disappear inside the same tube that the curtain, shade, or shutter wraps around. For OEMs, builders, and automation integrators, this combination of mechanical simplicity and installation cleanliness is a major advantage. But behind that streamlined exterior is a surprisingly sophisticated electromechanical system designed for consistent torque, precise travel control, and safe, reliable operation. To better understand how these mechanisms fit into the broader landscape of smart shading technologies, you can also explore our comprehensive guide to modern motor systems and their applications.

This article breaks down how a tubular motor works from the inside out—covering the motor unit, gearbox, braking structure, limit controls, wiring, installation considerations, and the safety mechanisms that keep the system stable under real-world use. If you're specifying motors for blinds, doors, or lightweight automation equipment, understanding these fundamentals will help ensure the right match between load and motor performance.

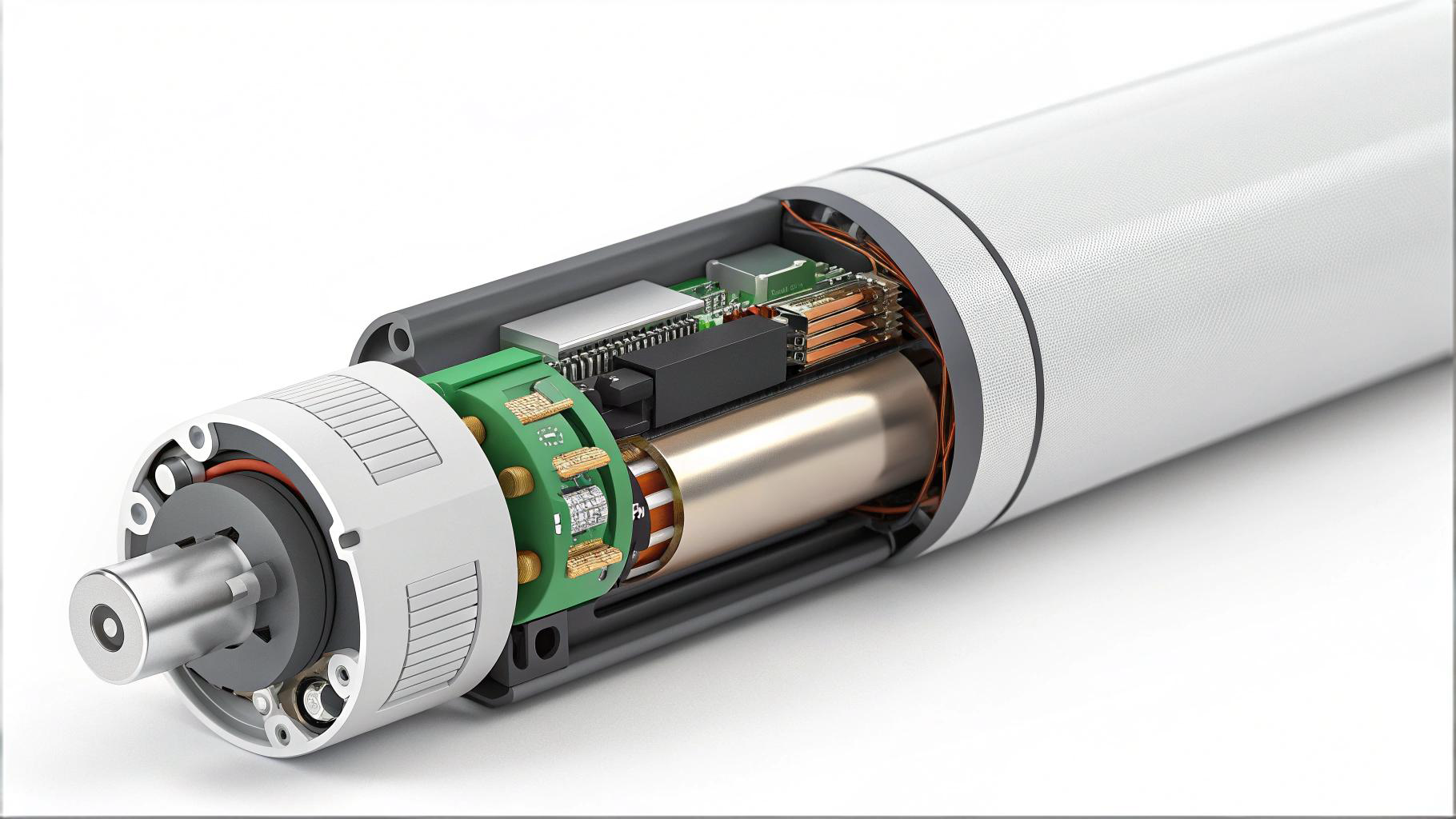

At the core of the system is a motor embedded inside a hollow cylindrical tube, often the same aluminum tube that carries the shade or shutter. This internal placement is more than an aesthetic choice; it's what gives tubular motors their minimal visual footprint and makes them so attractive in architectural and residential installations. By integrating the motor directly into the roller, manufacturers reduce external brackets, exposed drives, and bulky housings that would otherwise interrupt the clean profile of the window or door.

Inside the tube, the motor, gearbox, and limit control mechanism are arranged end-to-end. This linear form factor allows the unit to slot easily into standard roller tubes with only minor adjustments for diameter. It also creates a sealed electromechanical environment, protecting internal components from dirt, moisture, and accidental impact—key considerations for shutters and exterior facades.

At the heart of the system is a compact electric motor—typically an AC asynchronous motor for shutters and awnings or, increasingly, a DC motor in smart-home and low-voltage environments. When power is applied, the motor rotates an internal shaft. This rotation is transferred through the gearbox to produce the torque needed to turn the entire tube.

Depending on the load, manufacturers size motors anywhere from small units for lightweight fabric shades to higher-power solutions capable of lifting heavier steel shutters. Matching the motor to the load is critical. If the torque rating is too low, the system will struggle to lift the curtain or may overheat. If it's oversized, the installation becomes more expensive than necessary and may cause unnecessarily high noise or vibration.

One of the most important internal components is the gear reduction system. Tubular motors rely on either planetary gearing or worm-gear architecture to convert the motor's high-speed, low-torque rotation into slow, high-torque output. This gearing is what allows a motor only a few centimeters in diameter to lift a large roller shutter or heavy blackout blind.

Planetary gearboxes offer high efficiency, compact structure, and good load distribution. Worm gear systems, on the other hand, provide strong self-locking characteristics, which naturally enhance holding capability when the motor is not running. Manufacturers choose between these designs depending on the torque requirement, desired noise level, and target application.

Regardless of the gear type, the output of this reduction system connects directly to the tube. When the gearbox rotates, the entire tube turns—raising or lowering anything wrapped around it.

Another important aspect of tubular motors is their integrated braking or holding mechanism. When power is cut, the motor must stop immediately and hold position. Without this feature, gravity could cause the shutter or blind to drift downward, leading to safety issues or product damage.

The holding mechanism is typically mechanical, using the gearbox's inherent self-locking behavior or an additional brake system built into the motor assembly. This ensures the shade or shutter stays exactly where it was left—even in the absence of power.

Precise travel control is essential for anything that moves along a fixed path, and tubular motors use limit switches or electronic stroke controls to prevent over-travel. These limits define the fully open and fully closed positions.

Traditional tubular motors use mechanical cams inside the head of the motor. Adjusting the limits involves using a small screwdriver or dedicated adjustment tool to rotate these cams. Each cam corresponds to an endpoint. When the moving assembly reaches that point, the motor's circuit opens and the motion stops automatically.

More advanced digital or smart-home-ready systems use electronic sensors. These may be Hall-effect sensors, encoders, or current-sensing algorithms that detect load changes when an endpoint is reached. Electronic limits often self-calibrate and can be adjusted remotely through an app or home automation platform.

Because tubular motors are enclosed inside a tight metal cylinder, heat dissipation is an important design consideration. To protect the system, most motors include built-in thermal protection. If the motor operates continuously for too long—typically under heavy load or during repeated cycles—it will automatically shut down before overheating. Once the internal temperature drops back into a safe range, the motor resets and resumes normal operation.

In addition to thermal protection, many motors include overload detection. If a shutter is obstructed or frozen due to weather, the motor senses the abnormal load and stops to prevent mechanical damage. This is particularly important for exterior shutters and outdoor awnings, where environmental factors can impact movement.

Tubular motors use a straightforward wiring system:

Live + Neutral supply power

A direction control wire (often separate) sets up/down motion

A ground ensures electrical safety

For AC motors, direction is usually controlled by applying power to different leads. For DC motors, polarity switching or an internal control board sets the direction. Installation requirements vary by region and system type, but grounding and proper conductor selection are non-negotiable for safety and compliance.

Control methods can be as simple as a wall-mounted toggle switch or as advanced as an IoT-enabled interface using wireless protocols. Smart tubular motors integrate easily with building automation systems, allowing commands from sunlight sensors, schedules, temperature controllers, and voice assistants.

In commercial buildings or residential settings where shutters and blinds may protect windows or access points, power outages are inevitable. To maintain usability, many tubular motor models include a manual crank or clutch override. When engaged, this mechanism disconnects the motor drive and allows the tube to be rotated manually—an important safety and convenience feature, especially for exterior shutters on doors.

Installation: Precision Alignment for Smooth Operation

Although tubular motors are mechanically simple, installation quality has a major impact on long-term performance. The motor must be perfectly aligned with the roller tube and end brackets. If alignment is off, the tube may bind or rub, increasing friction, generating noise, or causing premature wear. Ensuring that the load is balanced across the tube helps the motor operate smoothly and prolongs the lifespan of both motor and curtain.

Installers must also ensure:

– Proper seating of the motor head into the mount

– Correct engagement of the drive wheel or crown with the tube

– Clean and unobstructed rotation path

– Accurate setting of limit positions

External environments require special attention to sealing around the motor head, gearbox, and bearing supports to prevent dust and moisture ingress.

Tubular motors are designed for low maintenance. There are no belts or external gears to lubricate. Still, periodic inspection is important in long-term installations.

Recommended checks include:

– Verifying limit positions remain accurate

– Inspecting mounting brackets and hardware

– Ensuring wiring connections are tight

– Confirming no obstructions interfere with motion

– Monitoring for unusual noise, vibration, or drifting

Properly installed, many tubular motors operate for years with minimal intervention.

Table: Comparison of Key Tubular Motor Features

|

Feature Category |

Mechanical Purpose |

Impact on Performance |

Typical Considerations |

|

Motor Unit |

Produces rotational motion |

Determines speed and core power |

AC vs. DC, power rating, noise |

|

Gear Reduction |

Increases torque, reduces speed |

Enables lifting heavier loads |

Planetary vs. worm, efficiency |

|

Braking Mechanism |

Holds shutter/blind in place |

Prevents drifting and slippage |

Self-locking, brake durability |

|

Limit Control |

Sets upper/lower stop points |

Prevents over-travel and damage |

Mechanical cams vs. electronic sensors |

|

Thermal/Overload Protection |

Prevents overheating & obstruction damage |

Extends motor lifespan |

Auto-reset time, load monitoring |

|

Control System |

Drives direction and automation |

Determines user experience |

Switch, remote, smart home integration |

As automation becomes an expectation rather than a luxury, tubular motors are playing an increasingly central role in both residential and commercial environments. Their seamless integration into roller systems, combined with increasingly intelligent control options, gives builders and OEMs a flexible foundation for energy management, privacy, and environmental control.

Smart-home platforms have accelerated demand for low-voltage and wireless-controlled versions, allowing users to automate shading based on sunlight intensity, temperature patterns, time schedules, or voice commands. In commercial spaces, tubular motors contribute to building energy efficiency by managing solar gain and indoor comfort without manual intervention.

Industry Insight:

As buildings place greater emphasis on energy optimization and occupant comfort, automated shading—powered by tubular motors—has become essential. The motor's reliability and predictability make it ideal for linking with sensors and building management systems, where consistent response and repeatability are critical.

Tubular motors combine mechanical efficiency, precise control, and architectural elegance in a single compact package. By embedding the motor inside the roller tube, manufacturers achieve a clean, minimalistic installation while still delivering the torque, consistency, and automation features today's end users expect.

For OEMs, integrators, and builders, understanding how tubular motors work—from motor and gearbox dynamics to control wiring and thermal protection—helps ensure the right product choice and long-term system reliability. As smart-home capabilities expand and building automation becomes mainstream, tubular motors will only grow in importance across residential, commercial, and industrial applications.

JIECANG has been deeply engaged in the research and development of Tubular Motors in the smart home field. If you need help specifying the right tubular motor for your smart home project, JIECANG can assist with technical comparisons, torque calculations, and motor-selection guidance.

Ф25mm DC tubular motor - Battery Powered

JCA35SS/JCA35SSL Roller Shade Motor Ф35mm AC roller shade motor kit

Venetian blind motor-Dual shaft output,The unique noise reduction and shock absorption structure design ensures that the motor runs quietly and smoothly, and brings users excellent and sustainable acoustic comfort. The motor running noise is <=31dB